Upgrade to ROS 2

Currently, the team uses ROS 1 Noetic, the final version in the ROS 1 series. Because it will be End-of-Life in 2025, it's important to plan a migration to a newer, supported version.

See what our teams have been up to!

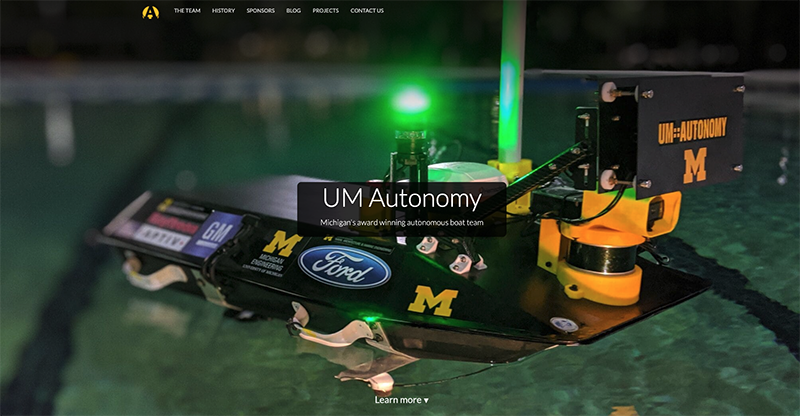

Building off of a Robot Operating System architecture,

AI tasks range from integrating COTS peripherals, to object detection,

navigation, top-level task reasoning, and simulating the boat’s

performance in a virtual competition course.

Tech stack: Docker-based environment, Git for version-control, ROS Noetic (with an upgrade planned) for the

architecture, and C++ & Python for the majority of the source code.

Currently, the team uses ROS 1 Noetic, the final version in the ROS 1 series. Because it will be End-of-Life in 2025, it's important to plan a migration to a newer, supported version.

The goal for CV deep learning is to implement deep learning models to accurately assign various classifications to objects detected by our boat’s camera. Upon completion, this new detection method will be integrated into our boat’s architecture, along with the development of a streamlined process for creating and training new models. Members will gain hands-on experience with one or more steps of the deep learning process, including model selection, design, training, and validation, as well as data annotation and preprocessing. Additionally, members may optionally also seek to gain a more theoretical understanding of deep learning models (and by extension, machine learning as a whole).

The Lidar quantification project’s goal is to explore metrics to evaluate our current LIDAR detection algorithm. These metrics give a more precise, fine-grained measure on the quality of the LIDAR detection than our current method of using a visualizer to holistically observe the results of the detection. Members will gain experience with researching and conceptualizing various evaluation metrics, then evaluating the “informativeness” of each metric using a small, annotated 3D point cloud dataset. Potential metrics include those typically used in the fields of machine learning or data science, as well as custom metrics that we may formulate ourselves.

The task planning team acts as the brains of our boat - it analyzes perception data in order to direct the movements of path-planning and controls. This will include creating an advanced movement library that interfaces with the path-planner/controller, enabling our boat to strafe, activate anchor mode, maneuver the boat relative to an obstacle, and circle around an obstacle. Expanding the boat’s current high-level logic capabilities, this new library interfaces with perception, path-planning, controls, and simulation. Task-planning members will achieve a broad understanding of all of the boat’s sub-teams. This team is great for someone who likes abstract, critical thinking without having to spend lots of team reading through ROS documentation, academic articles, or complicated math.

The Task Sim team’s goal is to build a simulated version of the RoboBoat competition tasks with Gazebo in order to test our boat code without an actual boat or water. This will involve testing the boat code as a single unit in its ability to traverse course obstacles, as well as constructing metrics to quantify and compare the performance of specific sections of the boat. Since we have a working simulator and some foundational code for path verification from previous semesters, existing code will be used and improved upon. Members of this team will gain experience with each section of the codebase, from perception to motion-modelling, by interfacing with and testing them, as well as experiencing simulation/physics engines.

The Electrical Team is responsible for the allocation of power to the boat and management of cables and wires from the battery to the computer, sensors, and motors.

Our main focus this year was to make the box more organized, neat, and reliable. To achieve these goals, we introduced numerous new parts and custom PCB’s. For example, this year we purchased a breakout board, which splits an ATX cable into its derivative voltage supplies. We also overhauled nearly every single electrical splice connection and adopted a more crimp-oriented approach as opposed to soldering everything.

Over the past couple of years, we have been utilizing custom-cut polycarbonate to construct the main “shell” of the electrical box. This year, we used a pelican box - a rigid, waterproof, and air-tight crate. In order to drill holes in the box for some inputs and outputs, we needed to expose members to different tools needed to penetrate the thick material. Although this process was time consuming, all of the sub-team members were able to contribute, learn a new skill, and the electrical box was completed almost two months ahead of where it was last year. We also built our electrical box based on a CAD model designed and completed last summer.

H&S Team works on the design and construction of the team’s boat. This includes designing around the boat’s electrical system, accompanying drone, and sensor specifications required by the boat’s autonomous systems.

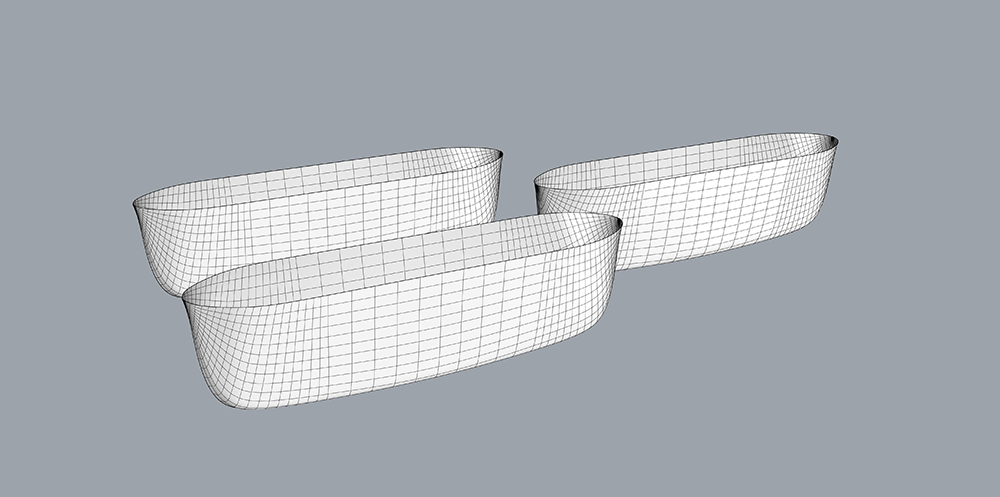

In recent years, the team has used a trimaran hull design which offers incredible stability. However, turning performance is limited due to the resistance offered by the hulls. The team will evaluate whether to keep or change the design in 2023.

In previous years, the team utilized pre-resin-impregnated, high-temperature curing carbon fiber cured in an autoclave to construct the hulls. This year, the hulls were constructed using a carbon fiber vacuum resin infusion process. Each demi-hull was fabricated using a machine-milled high-density foam mold produced for the team by the Ford Motor Company.

The Advanced Capabilities Team creates systems for competition elements that involve more than the base boat. Currently, we're tasked with creating a controllable water cannon and a mechanism that efficiently retrieves balls and places them into a storage bin. This involves using Computer-Aided Design (CAD) to physically build these systems, followed by designing the electrical circuits and sensors these components will use to function optimally. Finally, we'll create a communication platform to control these new features effectively.

This challenge will consist of three major steps: target recognition, calculating the water trajectory, and actuation. For target recognition, we will use camera-based computer vision system to detect and pinpoint target locations accurately. When it comes to trajectory calculation, we will calculate based on the position and orientation of both our vessel and the target. The actuation step will involve using the data gathered from the previous steps to properly align our water cannon. Once the cannon has been aligned, the water will be launched. To maintain “station keeping”—keeping our vessel still during the water launch—we will use force estimates to apply an opposite force via thrusters.

The boat will identify the collection zone, which is an octagon floating on the water’s surface. Once the area is detected, the ASV will then proceed to collect designated items—floating rubber ducks and red racquetballs. The detection will be mainly facilitated by our camera-based computer vision system.

After successfully collecting the items, the ASV will navigate towards the Delivery Octagon. Here, the vehicle’s primary task is to safely deliver the collected items. Points are awarded for not only delivering the items inside the octagon but also if items are delivered to the correct ‘nests’.

Throughout the process, the ASV needs to maintain efficient object handling and accurate navigational capabilities, which will be key to succeeding in this demanding challenge. The design and functionality of our vehicle will rely heavily on optimal strategies and technological advancements.

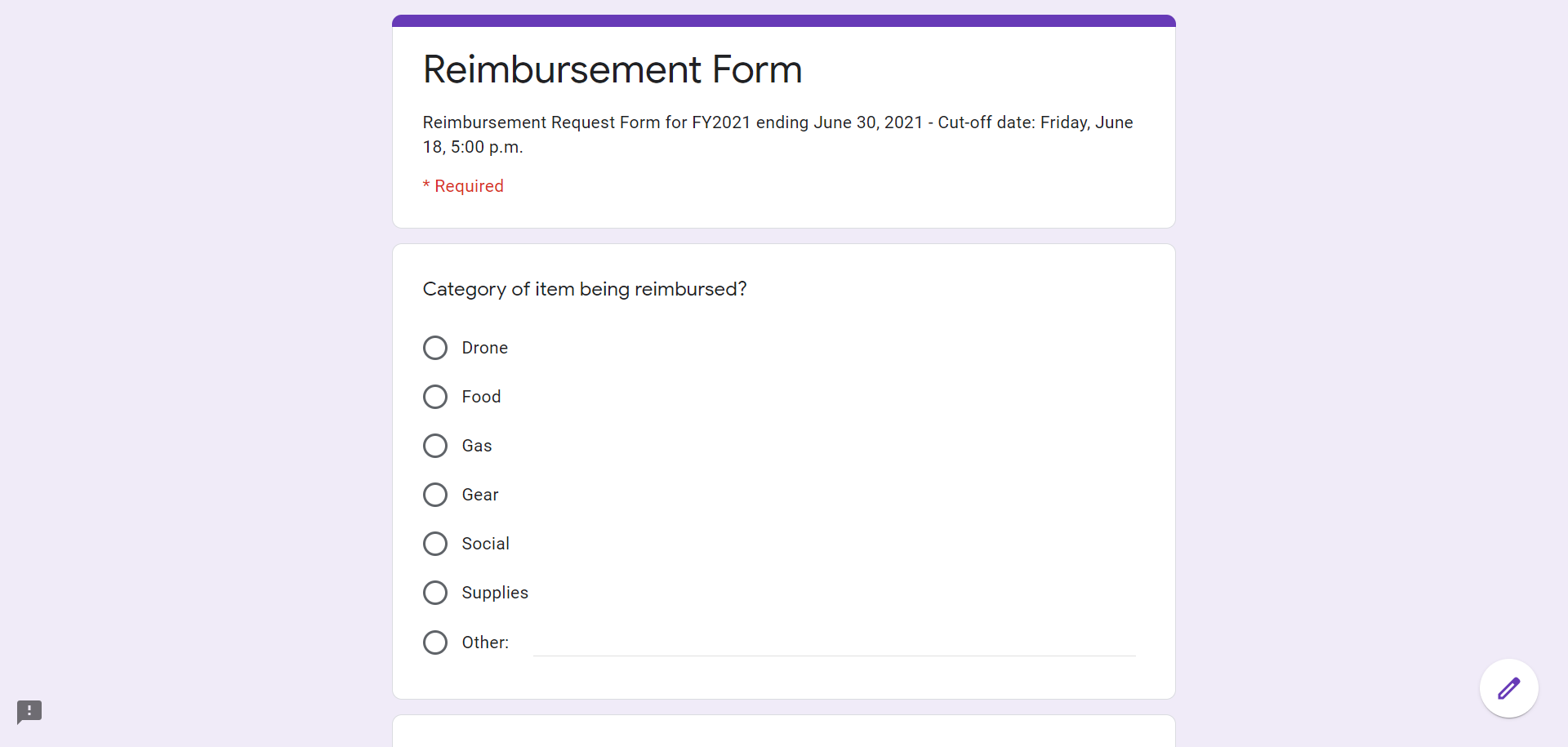

The Business Team secures funding for the team, processes reimbursement requests, maintains sponsor relationships and is responsible for social media engagement. The subteam also creates and maintains the team website.

We currently have a Google Form that requires separately uploading receipts for member reimbursement requests. While far better than the previous system involving manually notifying a team officer, we hope to introduce a streamlined system that allows receipt and description uploading quickly, which then immediately notifies the relevant person for purchase approval.

We hope to expand our social events even further than the previous year. In 2022-2023, we brought team members to a board game night, go-karting and arcade, and many team dinners after even work sessions. We also started a Minecraft server for members to play over the summer. However, we aim to have more frequent events, such as movie nights every other week.

With an effort to boost recruitment in 2023, several pages of the website have been redesigned to be more informative and appealing. Redesigns of several more pages are planned, and more content will be produced to further recruitment efforts, increase appeal to sponsors, and score more points in the RoboBoat website judging.

Members: Ben Schattinger